Alp co-led our team in developing our maintenance management system from the ground up. Right after construction, Alp helped us build an Operational Readiness plan. He played a pivotal role in our journey from commissioning to full production.

Operational excellence

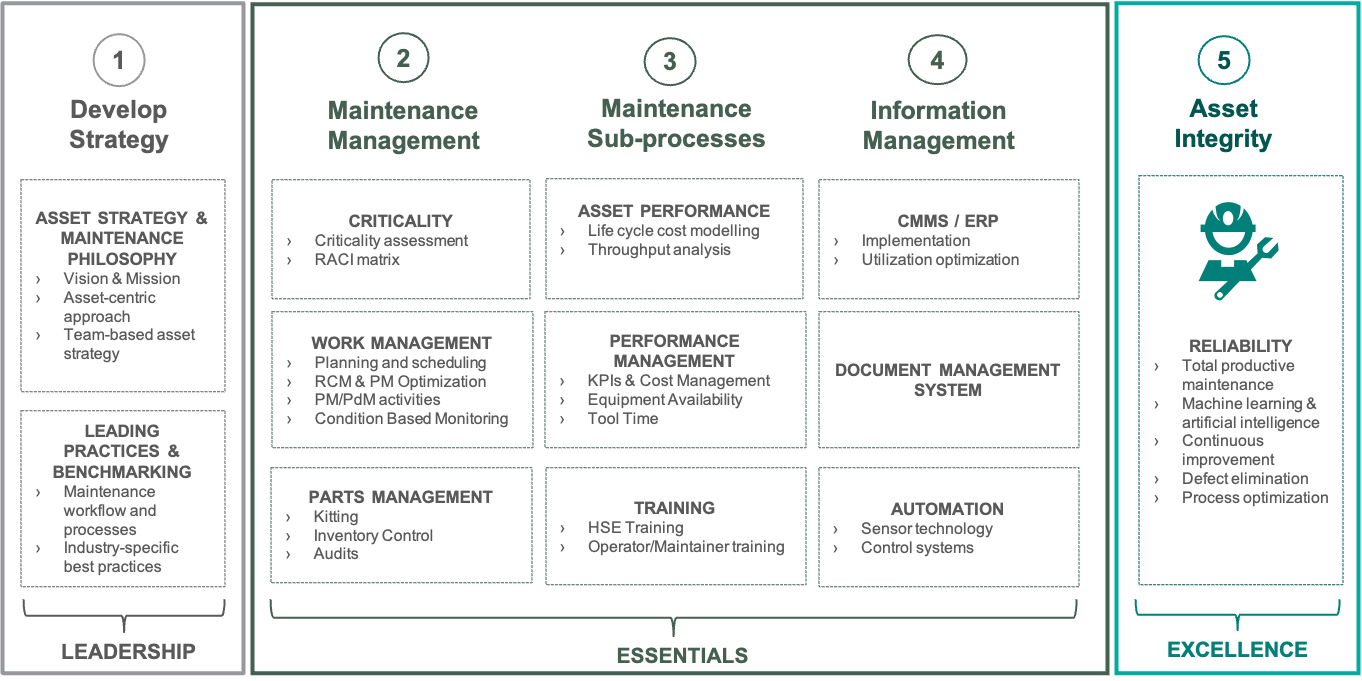

We help mining companies to achieve operational excellence

Our consulting framework is founded on 4 fundamentals of your business: People, Processes, Assets and Cash

Fire on all cylinders

Reduce maintenance backlog by 25%

Improve OEE by 10% - 20%

Optimize spare parts & kitting

20% Defect elimination over 12 months

Maintenance & Reliability

Enhance work practices

Increase asset availability

Reduce breakdowns

Eliminate maintenance wastes

© Bora Consulting 2021

Template by Bootstrapious. Ported to Hugo by DevCows.